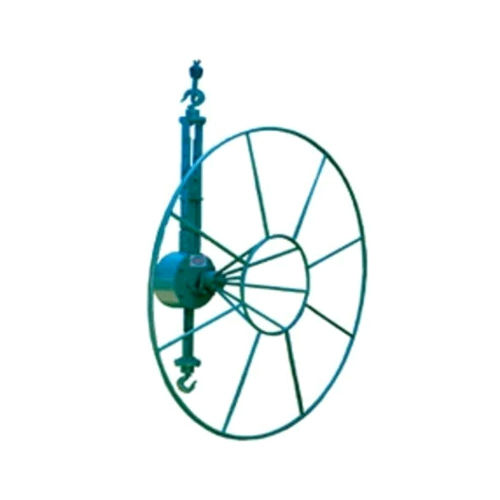

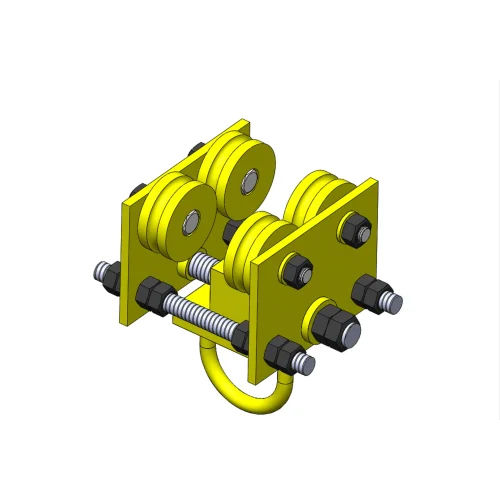

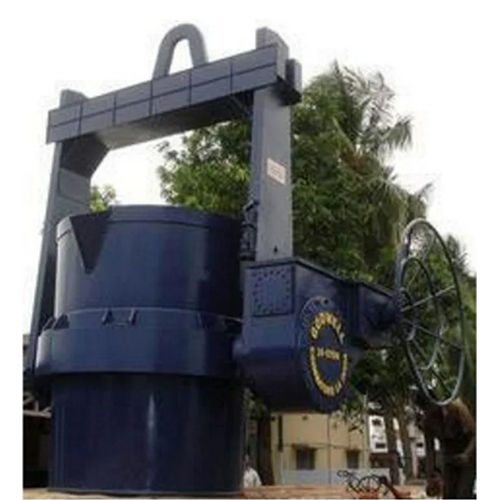

Globally famous for SG Iron Treatment Ladle, Taper Shell Treatment Ladle, SG Iron Treatment Ladle With EOT Operated Treatment Cover, Monorail Trolley, Drum Type Pouring Ladle, and more.

We, Godwell Engineering Products take pride in our commitment to manufacture the best, as we firmly uphold the principle that "Safety is as simple as ABC Always Be Careful" and "Absolutely NO Compromise."

Safety is paramount in every industry, particularly in foundries where the handling of molten metal poses significant risks. With over 50 years of expertise in the foundry sector, we have refined our molten metal handling products including, SG Iron Treatment Ladle, Taper Shell Treatment Ladle, SG Iron Treatment Ladle With EOT Operated Treatment Cover, Monorail Trolley, Drum Type Pouring Ladle, and more, to ensure they are fail-safe, robust, and exhibit exceptional durability and sustained performance, all while requiring minimal maintenance. Our Ladles comply with IS 4475 and IS 4476 standards.

Our operations are supported by a comprehensive array of machines and a team of well-qualified and experienced professionals. All this has helped us become one of the leading manufacturer, supplier, and exporter in the market.

A fundamental principle of our products is the commitment to the highest quality and safety without compromise. This dedication has established us as a leading supplier to esteemed foundries, including L&T Limited, Brakes India Limited Foundry Division, LMW Limited, Texmo Industries, Aquasub Engineering, Super Craft Foundry, and the Mutha and Mahle Groups, among others. Additionally, we export our ladles to markets in the Sultanate of Oman, UAE, Sri Lanka, and the Kingdom of Saudi Arabia.

Our Infrastructure

Our infrastructure facility spans 25,000 square feet on the outskirts of Coimbatore, South India, and is equipped with advanced machinery. Our design, production, assembly, and quality control departments are overseen by highly qualified engineers and experienced supervisors.

Our facility is equipped with an extensive array of machinery, supported by a team of highly qualified and experienced professionals, and adheres to the highest quality standards. We pride ourselves on our punctual deliveries and responsive after-sales service, which contribute to the remarkable value of our products in the marketplace.

The manufacturing plant spans 25,000 square feet on the outskirts of Coimbatore, India, and is equipped with advanced machinery capable of producing ladles with capacities ranging from 150 kg to 16 tons.

Why Us?

Listed below are a few other reasons for our success:

Safety is paramount in every industry, particularly in foundries where the handling of molten metal poses significant risks. With over 50 years of expertise in the foundry sector, we have refined our molten metal handling products including, SG Iron Treatment Ladle, Taper Shell Treatment Ladle, SG Iron Treatment Ladle With EOT Operated Treatment Cover, Monorail Trolley, Drum Type Pouring Ladle, and more, to ensure they are fail-safe, robust, and exhibit exceptional durability and sustained performance, all while requiring minimal maintenance. Our Ladles comply with IS 4475 and IS 4476 standards.

Our operations are supported by a comprehensive array of machines and a team of well-qualified and experienced professionals. All this has helped us become one of the leading manufacturer, supplier, and exporter in the market.

A fundamental principle of our products is the commitment to the highest quality and safety without compromise. This dedication has established us as a leading supplier to esteemed foundries, including L&T Limited, Brakes India Limited Foundry Division, LMW Limited, Texmo Industries, Aquasub Engineering, Super Craft Foundry, and the Mutha and Mahle Groups, among others. Additionally, we export our ladles to markets in the Sultanate of Oman, UAE, Sri Lanka, and the Kingdom of Saudi Arabia.

Our Infrastructure

Our infrastructure facility spans 25,000 square feet on the outskirts of Coimbatore, South India, and is equipped with advanced machinery. Our design, production, assembly, and quality control departments are overseen by highly qualified engineers and experienced supervisors.

Our facility is equipped with an extensive array of machinery, supported by a team of highly qualified and experienced professionals, and adheres to the highest quality standards. We pride ourselves on our punctual deliveries and responsive after-sales service, which contribute to the remarkable value of our products in the marketplace.

The manufacturing plant spans 25,000 square feet on the outskirts of Coimbatore, India, and is equipped with advanced machinery capable of producing ladles with capacities ranging from 150 kg to 16 tons.

Why Us?

Listed below are a few other reasons for our success:

- Timely delivery

- Strong market presence

- Years of experience